Mercedes Tie Rod End: Steering Rack and Pinion Impact

Rack and pinion steering is an essential component of modern vehicle technology, providing precise control and efficient handling. In this blog, We'll explore everything you need to know about Mercedes rack and pinion steering, how tie rod ends contribute to the system, and the potential issues and maintenance tips to keep your vehicle in top shape. Whether you're curious about how these components work together or looking to maintain optimal vehicle alignment, this guide will help you understand the intricacies of Mercedes steering systems.

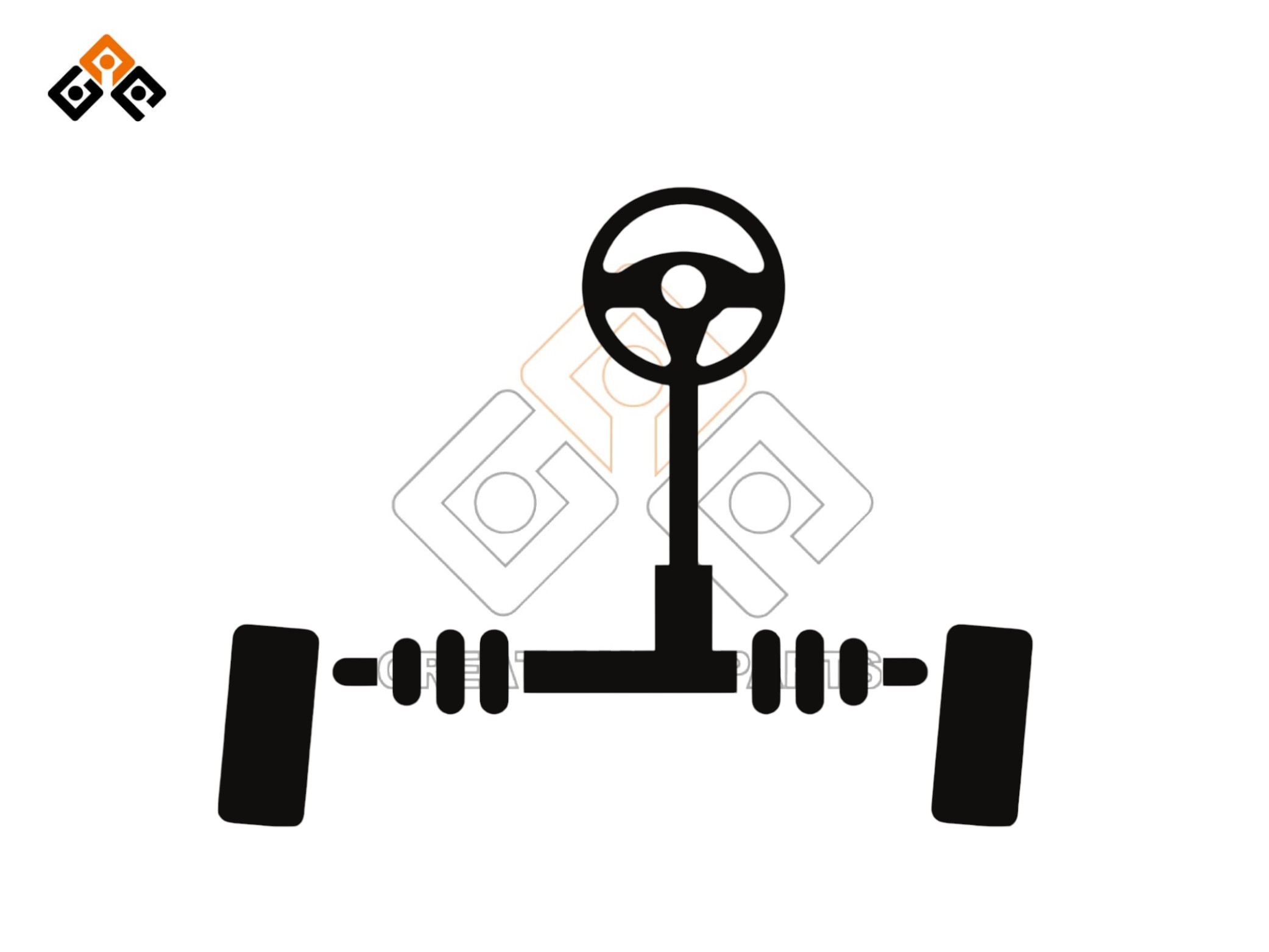

What Is Rack and Pinion Steering and How Does It Work

Rack and pinion steering is a commonly used type of steering mechanism in modern vehicles. The system is made up of two key components: the rack, a long bar with teeth, and the pinion gear, a small round gear connected to the steering wheel. When the driver turns the steering wheel, the pinion gear rotates, which moves the rack in a linear direction. This linear movement is what ultimately turns the wheels left or right, giving the driver precise control over the vehicle's direction.

This mechanism converts the rotational motion of the steering wheel into linear motion needed to control the wheels. Due to its direct steering feel, rack and pinion systems are widely used in passenger cars, providing drivers with enhanced precision and responsiveness. Its design is simpler compared to other steering systems, making it ideal for smaller vehicles like cars and SUVs.

How Does Power Steering Enhance Rack and Pinion Systems

Power steering enhances rack and pinion systems by reducing the effort required to turn the steering wheel. This is especially beneficial when driving at low speeds or when maneuvering in tight spaces, such as parking. Power steering can be hydraulic or electric, and both types provide additional assistance to make the steering smoother and easier.

| Category | Hydraulic Power Steering | Electric Power Steering |

| Working Principle | Uses an engine-driven pump to generate hydraulic pressure to assist the movement of the rack when the steering wheel is turned. | Uses an electric motor to provide steering assistance without relying on engine power. |

| Power Source | Hydraulic pressure provided by an engine-driven pump. | Electric motor powered by the vehicle's battery. |

| Steering Assistance Feature | Provides more assistance at low speeds and reduces assistance at higher speeds, ensuring precise control. | Similarly adjusts the level of assistance based on speed, ensuring precise control in various driving conditions. |

| System Response | Slower response, especially in cold conditions or when the hydraulic pump efficiency decreases. | Faster response, with immediate adjustments in assistance, making the system more responsive. |

| Energy Consumption | Increases fuel consumption as it relies on engine power to drive the hydraulic pump. | More energy-efficient, powered by the battery, particularly advantageous in electric vehicles. |

| Maintenance Needs | Requires regular checks of hydraulic fluid and components, leading to higher maintenance costs. | Lower maintenance needs as there is no need for hydraulic fluid, making it easier to maintain. |

| Applicable Vehicle Types | Commonly used in traditional internal combustion engine vehicles. | More frequently adopted in modern vehicles, particularly hybrids and electric cars. |

| Driving Experience | Provides a more traditional steering feel with greater road feedback but less comfort. | Offers smoother and more responsive steering, particularly suitable for city driving and precise control. |

| City Driving Maneuverability | Enhances maneuverability in urban environments, but response may not be as quick as in electric systems. | Provides higher agility in crowded streets and during quick lane changes, making steering lighter and more responsive. |

| Advantages | Suitable for high-performance or heavy-duty vehicles as hydraulic systems can provide stronger assistance in certain scenarios. | Energy-efficient and highly responsive, ideal for modern electric vehicles and situations requiring variable assistance. |

Advantages and Disadvantages of Rack and Pinion Steering Compared to Other Systems

| Aspect | Rack and Pinion Steering System | Other Steering Systems (e.g., Recirculating Ball System) |

| Simplicity | Fewer parts, less friction, fewer potential failure points, cost-effective, and lower maintenance needs. | More complex, with more parts requiring lubrication and potential failure points, but stable in heavy-duty vehicles. |

| Precision and Responsiveness | Direct connection between the steering wheel and the rack provides more precise steering, especially in sharp turns or tight spaces. | Less road feedback, lower steering sensitivity, and more steering play, reducing precision. |

| Weight and Efficiency | Lighter system, which improves fuel efficiency and overall vehicle performance. | Heavier and more complex system, typically used in larger or heavier vehicles, potentially increasing fuel consumption. |

| Durability | Less durable in heavy-duty vehicles (e.g., trucks) compared to recirculating ball systems. | More durable, suitable for heavy-duty vehicles, and able to withstand larger loads and harsher operating conditions. |

| Application | Best suited for light to medium vehicles, especially passenger cars, providing more responsive handling. | Suited for heavy-duty vehicles, such as trucks or off-road vehicles, providing stronger steering force. |

| Repair Complexity | Repairs can be more complex and costly when the system fails. | More parts make repairs more involved, but in some cases, standardized components can make repairs relatively less costly. |

Common Issues with Rack and Pinion Steering and Essential Maintenance Tips

Common Issues

- Leaking Power Steering Fluid: Often caused by worn-out seals or O-rings, leading to less responsive steering.

- Loose or Tight Steering Wheel: A loose steering wheel may indicate worn components, while a tight wheel can point to issues with the power steering pump or fluid levels.

- Strange Noises: Grinding or clunking sounds when turning the steering wheel may indicate internal damage or worn components.

Maintenance Tips

- Regular Fluid Checks: Check power steering fluid levels and replace as recommended by the manufacturer.

- Inspect for Leaks: Regularly inspect the system for fluid leaks to prevent more serious damage.

- Listen for Noises: Pay attention to unusual noises and address them promptly to avoid further damage.

- Regular Inspections: Have the steering system inspected regularly by a professional, especially if there are changes in steering performance.

How Is the Steering Rack Connected to Tie Rod Ends

The connection between the steering rack and tie rod ends is critical to the functioning of the steering system. The rack and pinion gearset converts the steering wheel's rotational movement into linear motion, which moves the wheels left or right. The tie rods play an essential role in transmitting this movement to the wheels.

Each end of the steering rack is connected to a tie rod. The tie rods link the rack to the steering arms on the wheels, allowing the linear movement generated by the rack to be effectively transferred to the wheels. This setup ensures that the vehicle responds accurately to the driver's steering input, making the car easier to handle and control.

Primary Components Involved in the Rack and Tie Rod Connection

Several primary components are involved in the connection between the steering rack and the tie rod ends:

- Steering Rack:

The main component housing the rack and pinion gearset. It converts the steering wheel's rotation into the movement needed to turn the wheels. - Pinion Gear:

Attached to the steering shaft, the pinion gear engages with the teeth on the rack to create the linear motion needed for steering. - Inner Tie Rod Ends:

These are connected directly to the ends of the steering rack and transmit the motion from the rack to the outer tie rod ends. - Outer Tie Rod Ends:

These connect the inner tie rod ends to the steering knuckles, allowing for the pivoting motion necessary to turn the wheels. - Tie Rod Adjusting Sleeves:

Used to adjust the length of the tie rods to ensure proper alignment of the wheels. - Steering Knuckles and Ball Joints:

These connect the tie rod ends to the wheels, allowing for smooth pivoting and precise wheel movement.

These components work together to ensure that the driver's input is effectively transmitted to the wheels, allowing for precise and reliable vehicle control.

How Do Tie Rod End Adjustments Affect Vehicle Alignment and Handling

Adjusting the tie rod ends is crucial for maintaining proper vehicle alignment and handling. The toe setting is the primary alignment adjustment that involves the tie rod ends. Toe refers to the angle at which the tires point inward or outward. Proper toe alignment ensures that the tires are parallel and perpendicular to the road, which improves steering precision and reduces tire wear.

Tie rod adjustments also help with steering wheel centering. If the steering wheel is not centered while driving straight, adjusting the tie rods can correct this issue, improving overall vehicle handling. Proper adjustment is also essential for tire wear and stability. Misaligned tie rods can cause uneven tire wear and make the vehicle feel unstable, especially at higher speeds.

Upgrade Your Mercedes’s Handling with High-Quality Tie Rod Replacements

When it’s time to replace your tie rods, selecting the right components can significantly improve your Mercedes's handling and ensure lasting reliability. Here’s why Great Auto Parts tie rod ends are an excellent choice for enhancing your vehicle:

- Built to Last:

Constructed from high-strength steel and manufactured using advanced forging techniques, ensuring exceptional durability. - Corrosion-Resistant:

Treated to resist rust, providing long-term protection and extending the lifespan of the tie rod ends. - Enhanced Flexibility:

Engineered with a wide swing angle of at least 60 degrees, allowing for better steering control and smoother handling. - Superior Strength:

Designed to meet or exceed original equipment standards, ensuring unmatched durability and reliability. - Perfect Fit:

Precisely crafted to replace the original tie rod ends seamlessly, offering a hassle-free installation experience. - Small Order Advantage:

Available with a minimum order quantity of just 30 pieces, making it ideal for small businesses seeking quality parts in smaller volumes.

Choose Great Auto Parts for a smoother, more reliable driving experience in your Mercedes, with parts built for exceptional performance and long-lasting quality.